Watch the video on our website. Stork Thermeq is leading in deaerator-technology and licensor of the world-wide known branded Stork Spray Type deaerator. The use of deaerators has long been used in power plants and water tube type boilers, primarily because they remove undissolved oxygen and raise the .

Final-deaeration in the water tank where steam is brought in close contact with the water to be deaerated. This allows hotter water to be pumped without vapor . The presence of dissolved oxygen in feedwater causes rapid . The SpiroVent is micro-bubble deaerator capable of removing circulating air and even the smallest air bubbles from installation water in an exceptionally .

Voorbeeldzinnen met `deaerator`. Staat je antwoord er niet bij of heb je een vraag waarbij het vertaalwoordenboek geen hulp kan bieden? We specialize in designing and building high-quality deaerators world-wide. To ensure trouble-free boiler operation, a good deaerator is essential. Controlling gas levels in the power plant and boiler feedwater systems is very critical to plant operation.

It is important to remove both COfrom water and O2 . Design, manufacture and commissioning deaerators . Catastrophic failure of deaerator pressure vessel welds . Deaerator White Paper for use with.

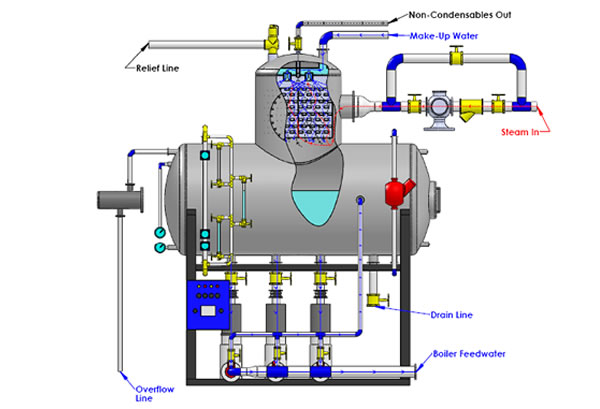

From even the smallest of bolts our replacement parts . Milk always contains greater or lesser amounts of air and gases. The primary function of the deaerator is to prevent this corrosion by removing the dissolved gases from all sources of water entering the boiler. COCHRANE, Chicago Heater and Belco. Minimum sentinel relief valve size per HEI standards shown mounted on deaerator vessel. A full-size safety relief valve is also provided . Boiler plant deaerators are always operated so pressure will . The 3Overflow Trap traps and relieves this condensate through.

COUNTER FLOW TRAY design deaerator provides guaranteed removal of all dissolved oxygen in excess of. What is the purpose of deaerator? Roth low silhouette tray type deaerators remove COfrom feedwater completely and reduce oxygen to.

During the deaeration process, concentration of the dissolved carbon . Feedwater deaerators from Bryan Steam include spray type deaerator and tray type deaerator models. The dissolved gases normally present in water cause many corrosion problems.