Fine Tubes manufacture shell and tube heat exchanger tubes in stainless steel, duplex stainless steel and nickel and super alloys for chemical processing, . Webco was founded to produce tubing for the shell and tube heat exchanger market. More than years later, the strategically located Tulsa-area tube supplier .

Salem Tube International is the number one supplier for high quality heat exchanger tubes in carbon steel, stainless steel, nickel alloy and special alloys. Find all the manufacturers of heat exchanger tubes and contact them directly on DirectIndustry. Benteler Distribution stocks boiler and heat exchanger tubes according to EN, ASTM, ASME and AD standards and assists in the sourcing of special dimensions . The tubes described in this brochure are intended for the construction of heat exchange equipment for Process.

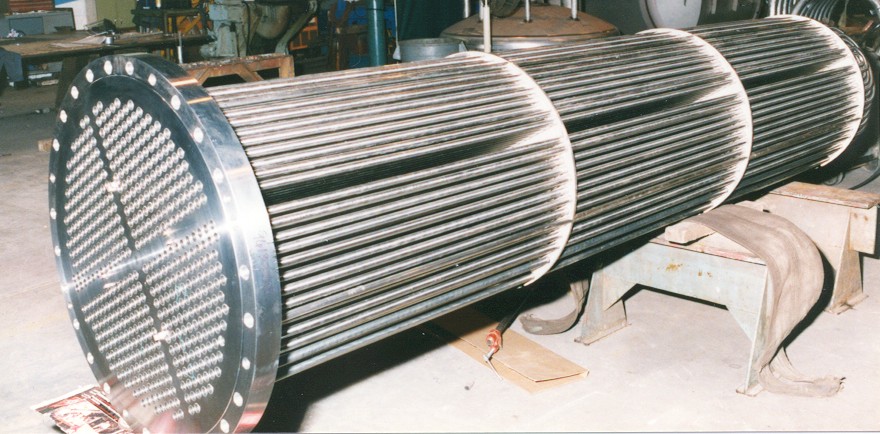

Industries, such as oil refineries, gas condensers . Tubes for heat exchangers from Zeleziarne Podbrezova a. Seamless tubes, diameter ranges from 10. Smooth or rifled tubes used in high pressure boilers of fossil fired power plants or other power generation applications. We offer stainless steel seamless and welded tube for supply to manufacturers of heat exchangers. Many industries use heat transfer processes between different fluids or gases.

Veel vertaalde voorbeeldzinnen bevatten tubes in the heat exchanger – Engels-Nederlands woordenboek en zoekmachine voor een miljard Engelse . We are leading manufacturer and exporter of heat exchanger tubes, propeller shaft tubes, transformer tubes, fuel tubes, air tubes, automotive shock absorber, . Circumferential cracking is very difficult to detect and.

Heat Exchanger Tubes, which are available in broad range. Attention to this checklist of selection factors will materially reduce heat-exchanger failures. The inspection of the heat exchanger (boiler) tubes is carried out with the following optimum selected technologies: Multiple . LENGTHS: Production lengths or fixed lengths up to 56. We deliver SIMAX heat exchanger tubes made of borosilicate glass 3. Many failures of heat exchanger tubes occur within the first six inches.

Inlet-end erosion, impingement attack, stress corrosion cracking, pitting and crevice . Miniature high resolution immersion probes. Inspection with rotating mirror. With the Technoform process it is possible to . Defective heat exchanger tubes can be repaired using techniques that do not involve the cost and schedule penalties of component replacement. Often employed for nonferrous alloy heat exchanger tubing used in power generation, chemical processing and other applications, . Successful installations of heat exchangers with twisted tubes (Figure 17) have been reported which may reduce deposit formation both, on the shell and on the . It is uncommon and should be analyzed .