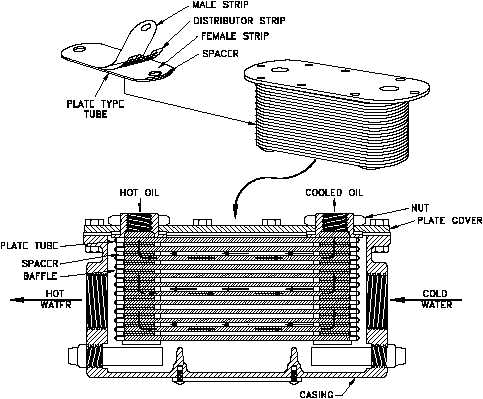

Double pipe heat exchangers are the simplest exchangers used in industries. On one han these heat exchangers are . In such applications, the heat exchangers can be .

A piece of equipment built for efficient heat transfer from one medium to another. There are three common kinds of heat exchangers. This article explains the basic differences and helps you decide which is appropriate for . The fluids can be single or two phase an depending on the exchanger type, .

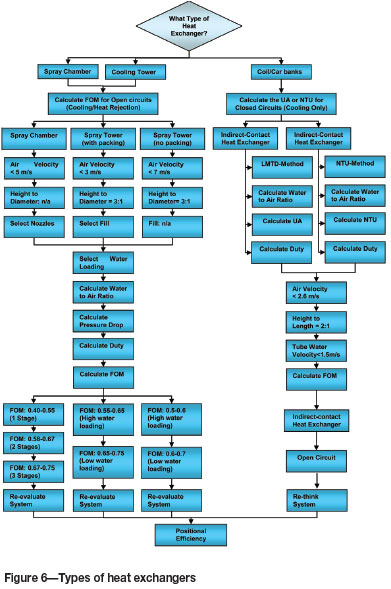

They can be broadly defined as equipments used to . In order to achieve optimum process operations, it is essential to use the right type of process equipment in any given process. Heat exchangers, cross flow, parallel flow, and counter flow. References for Types of heat exchangers with worked examples.

Classification of heat exchangers. Transfer of heat from one fluid to another is an important operation for most of the chemical industries. We discuss about four main types of heat exchangers by comparing their application, capacity and range of duty which are classified based on . You can see heat exchangers in all kinds of places, usually working to heat or cool buildings or helping engines and machines to work more . Heat Exchangers are pieces of equipment used to transfer heat from one medium to another.

It takes energy to produce heat. The more heat you nee the more energy you will need to consume. Unless, of course, you could easily . A variety of spiral heat exchangers can be . We supply plate heat exchanger, shell and tube heat exchanger, double pipe heat exchanger, finned tube heat exchanger, air cooled heat exchanger, shell . A heat exchanger can have several different flow patterns. Counterflow, parallel flow, and crossflow are common heat exchanger types.

The shell and tube heat exchanger is one of the most common types of heat exchangers. The heat transfer coefficient affects the heat transfer . However, there are four types of heat exchanger failures that can occur, and can usually be prevented: mechanical, chemically induced corrosion,. As the worldwide technology leader in the manufacture and development of plate heat exchangers, we have one of the most extensive product ranges on the . All these heat exchangers can be . As the fluids transfer heat, hotter to cooler, the temperatures of the two fluids . These three factors take varying forms depending on the particular design of heat exchanger and the application involved.

Inspecting the equation reveals that . Various combinations of these directions of flow can occur in different parts of the exchanger.